What is Industrial Automation?

Estimated Reading Time: 7 minutes

Key Takeaways

- Industrial automation leverages advanced control systems and robotics to boost efficiency.

- Smart factories use real-time data processing and IoT for proactive maintenance.

- Cobots collaborate with humans while industrial robots excel in heavy-duty tasks.

- Choosing the right automation tools is key to optimizing production.

Table of Contents

In this post, we’ll explain how robots are used in smart factories, elucidate the difference between cobots vs industrial robots, and review the best industrial automation tools along with compelling robotics case studies in manufacturing.

We’ll delve into both the informational aspects of learning about industrial automation and provide guidance for those looking to invest in automation tools for their operations.

Defining Industrial Automation

Industrial automation can be defined as the integration of control systems, computers, and robotics that manage industrial machinery and processes autonomously or with minimal human involvement. This evolution from simple mechanization to sophisticated automation marks a significant leap in manufacturing capability.

Key elements of industrial automation include:

- Integration of Control Systems: These systems coordinate machinery, transport materials, and monitor performance.

- Use of Computers: Central to controlling processes and gathering data for decision-making.

- Advanced Robotics: Automated machines that perform tasks with precision and speed.

According to research from Unitronics, Industrial automation is the use of control systems, computers, and advanced technologies to manage various processes and machinery

. ARM further supports this definition, emphasizing the replacement or augmentation of human intervention in various industrial processes (source: ARM).

The best industrial automation tools are essential for implementing these systems efficiently, which we’ll elaborate on later.

How Robots are Used in Smart Factories

Smart factories are the backbone of modern industrial automation. They utilize interconnected systems, advanced sensors, and automated machinery to create a highly efficient production environment. But how are robots used in these smart factories?

Robots play several critical roles:

- Real-time Data Processing: Smart factories leverage data to optimize production processes by analyzing real-time metrics.

- Preemptive Maintenance: Sensors on machines trigger maintenance actions, preventing unexpected downtimes (source: Oracle). You can also learn more about this process in our post on What is Predictive Maintenance in Manufacturing?.

- Automation of Hazardous Tasks: Robots handle functions such as welding and heavy lifting to improve workplace safety (source: Oracle).

- Logistics Handling: Automated Guided Vehicles (AGVs) assist in transporting materials across factory floors, enhancing logistics efficiency.

- Quality Assurance: Vision systems integrated into robots inspect parts for defects, ensuring consistent production quality.

For further insights on technologies that optimize factory processes, check out our post on What is a Digital Twin in Manufacturing? Understanding Its Role and Benefits in Smart Factories.

Difference between Cobots vs Industrial Robots

Understanding the difference between cobots and industrial robots is crucial as both serve unique purposes within manufacturing:

Cobots (Collaborative Robots)

- Designed to work safely alongside human operators.

- Smaller, lighter, and more flexible than traditional robots.

- Easily reprogrammable, making them ideal for environments that require frequent changes.

- Perfect for tasks needing direct human interaction.

Industrial Robots

- Larger, faster, and more powerful machines.

- Typically used in high-volume and precision tasks where safety cages are necessary.

- Excels in repetitive, intensive jobs, better suited for heavy-duty applications.

The operational capabilities of cobots allow for greater flexibility, while industrial robots focus on efficiency and speed. This leads businesses to choose either based on the specific demands of their production processes.

Research highlights the functional benefits of both types of robots, citing advantages such as improved safety and productivity in manufacturing settings.

Best Industrial Automation Tools

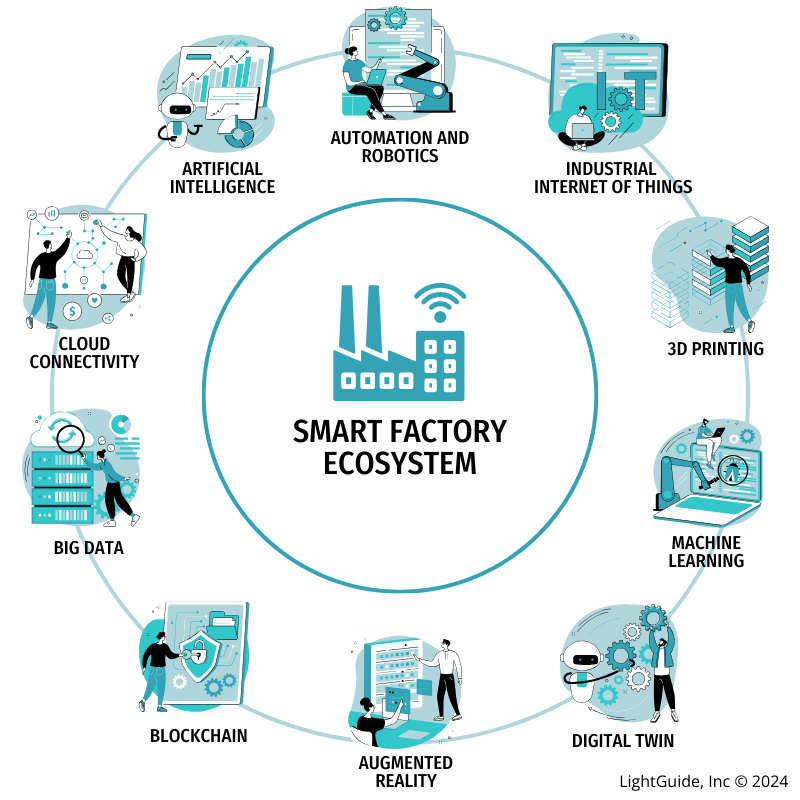

When delving into industrial automation, it’s vital to explore the best industrial automation tools available. Here are some noteworthy technologies that drive the efficient operation of automated systems:

- Programmable Logic Controllers (PLCs): Essential for controlling machinery and automating various processes within manufacturing settings.

- Artificial Intelligence (AI) and Machine Learning: These applications focus on predictive maintenance and optimizing production workflows, adjusting processes in real time.

- Internet of Things (IoT) Devices: Used for real-time monitoring of equipment, enhancing communication across systems, allowing for seamless process automation. For further context on integrating IoT devices within modern plants, check out Understanding IIoT Platforms: Key Features, Benefits, and Future Trends.

- Sensors and Actuators: They provide crucial data for monitoring processes and executing control functions, which enhances responsiveness. To dive deeper into sensor technology and its role in manufacturing, read our post on Top 5 Best IIoT Sensors for Manufacturing: Enhance Efficiency and Reliability.

- Advanced Robotics Systems: Represent the cutting edge of automation, integrating with smart factory operations to facilitate advanced manufacturing processes. See how AI advances these systems in our article How AI is Transforming Industrial Automation: Enhancing Efficiency, Quality Control, and Future Trends.

Selecting the right tools hinges on specific production needs, including volume, task complexity, and human interaction levels. Research emphasizes considering these factors for effective tool selection.

Robotics Case Studies in Manufacturing

Case Study 1: Ford’s Dearborn Factory

At Ford’s Dearborn factory, AGVs transport vehicles between workstations while AI-based analysis supports robust welding quality control (source: Oracle). This integration has resulted in streamlined operations and reduced manual labor.

Case Study 2: LG Electronics

LG is implementing smart production technologies across 26 production facilities in 13 countries. This initiative has led to significant efficiency gains and an overall boost in production capabilities (source: Oracle).

Case Study 3: Zuellig Pharma

Zuellig Pharma employs AR-enabled drones for inventory management, achieving dramatic improvements in productivity and accuracy—reporting a 30% increase in pick productivity and achieving 100% accuracy (source: ABI Research).

Conclusion & Call-to-Action

In summary, we have explored the key themes surrounding industrial automation, defining what it is, examining how robots are utilized in smart factories, and distinguishing the differences between cobots and industrial robots. Additionally, we reviewed the best industrial automation tools available and illustrated their impact with practical case studies in manufacturing.

The advantages of industrial automation are clear: increased productivity, improved quality, enhanced workplace safety, and reduced operational costs. For businesses contemplating investments in these solutions, evaluating specific needs and consulting automation experts is critical to successful implementation.

If you are interested in exploring how industrial automation can benefit your operations or wish to learn more about implementing these technologies, consider reaching out to automation experts or visiting reputable industrial automation providers today. *Embrace the future of manufacturing with industrial automation, where efficiency meets innovation!*

FAQ

What is industrial automation?

Industrial automation is the use of control systems, computers, and advanced technologies to manage various processes and machinery with minimal human intervention, thereby increasing efficiency and productivity.

How can industrial automation improve manufacturing efficiency?

By integrating interconnected systems that monitor and adjust production processes in real time, industrial automation minimizes downtime, improves quality control, and enhances overall operational performance.