Top 5 Best IIoT Sensors for Manufacturing: Enhance Efficiency and Reliability

Estimated Reading Time: 12 minutes

Key Takeaways

- IIoT sensors are crucial for real-time monitoring and data-driven decision-making in manufacturing.

- Implementing IIoT devices can lead to significant productivity improvements and downtime reductions.

- Predictive maintenance enabled by IIoT sensors helps in preventing costly equipment failures.

- Edge devices enhance IIoT performance by processing data locally, reducing latency and bandwidth usage.

- Choosing the right connectivity protocols is essential for the success of IIoT systems.

Table of Contents

- Introduction

- Understanding IIoT Sensors

- How IIoT Devices Improve Production Efficiency

- IIoT-Enabled Predictive Maintenance Sensors

- Role of Edge Devices in IIoT

- Connectivity Protocols in IIoT

- Top 5 Best IIoT Sensors for Manufacturing

- Implementing IIoT Sensors in Your Manufacturing Process

- Conclusion

- Additional Resources

Introduction

The Industrial Internet of Things (IIoT) is transforming the manufacturing landscape, generating significant advancements in efficiency, productivity, and innovation. Selecting the best IIoT sensors for manufacturing is essential to fully harness the opportunities that this transformative technology offers. IIoT devices improve production efficiency by gathering real-time data and delivering actionable insights, leading to smarter decision-making and optimized operations.

This blog post will guide manufacturers in choosing the best IIoT sensors while highlighting their benefits in enhancing production processes and enabling predictive maintenance.

For a detailed understanding of IIoT and its importance, refer to the definition from TechTarget: Industrial Internet of Things (IIoT).

Understanding IIoT Sensors

What Are IIoT Sensors?

IIoT sensors are intelligent devices that collect, transmit, and analyze data from industrial equipment and processes. They form the backbone of IIoT implementations, enabling real-time monitoring and data-driven decision-making.

The Role of IIoT Sensors in Manufacturing

These sensors are fundamental to optimizing manufacturing operations by providing actionable insights that improve efficiency and reduce waste. Their capabilities include:

- Real-time Monitoring: Continuous data tracking leads to instantaneous responses to operational changes.

- Data-Driven Decisions: Data analytics assists in making informed decisions that enhance production quality. Multi Agent Systems: A Comprehensive Guide to Scaling AI Agents for Business

- Process Optimization: Organizations can fine-tune processes based on sensor inputs, improving efficiency. Multi Agent Systems: A Comprehensive Guide to Scaling AI Agents for Business

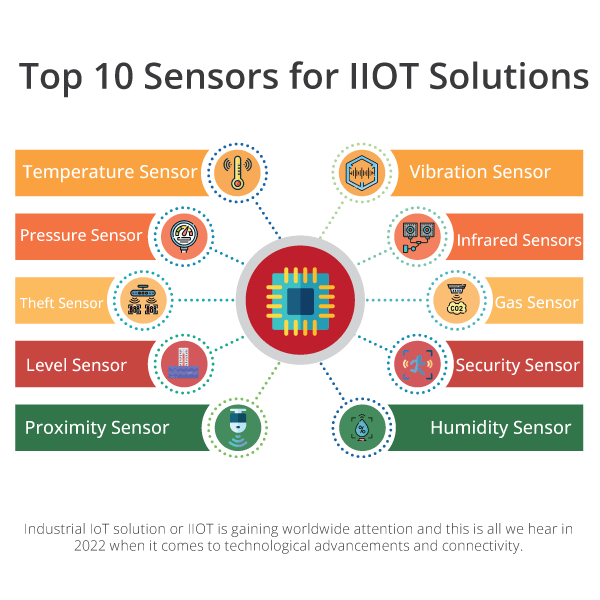

Types of IIoT Sensors

Manufacturers commonly employ various IIoT sensors, including:

- Temperature Sensors: Monitor heat levels, crucial for sensitive equipment.

- Pressure Sensors: Measure force within systems, essential for maintaining operational integrity.

- Vibration Sensors: Detect abnormal vibrations indicating potential equipment failure.

- Flow Sensors: Measure the movement of liquids or gases in systems.

- Proximity Sensors: Identify presence or absence without contact.

Understanding these different sensor categories is vital for implementing the appropriate technology within your operations.

For a comprehensive overview of IIoT sensors, refer to TechTarget’s explanation: IIoT Sensors.

How IIoT Devices Improve Production Efficiency

Enhancing Production Workflows

IIoT devices revolutionize production workflows through:

- Real-time Monitoring: Facilitate immediate visibility into operations, allowing timely interventions.

- Automation: Streamline processes, reducing human error and labor costs. Multi Agent Systems: A Comprehensive Guide to Scaling AI Agents for Business

- Data Analytics: Analyze operational data to uncover trends and improvement opportunities. OpenAI Deep Research: Revolutionary AI Tool Transforms Professional Research Capabilities

By incorporating IIoT technology, manufacturers have reported remarkable productivity gains and decreased downtime. Specifically, companies have achieved:

- Up to 25% Improvement in Productivity: The use of IIoT devices can lead to significant enhancements through increased process efficiency and resource management.

- 45% Reduction in Downtime: With constant monitoring, businesses can anticipate issues before they escalate, allowing for proactive measures to maintain operational flow.

For further insights into how IIoT can enhance production efficiency, explore PTC’s findings: IIoT and Predictive Maintenance.

IIoT-Enabled Predictive Maintenance Sensors

What Is Predictive Maintenance?

Predictive maintenance uses real-time data from IIoT-enabled sensors to forecast potential equipment issues before they arise. This proactive approach is pivotal in maintaining operational efficiency and preventing costly breakdowns.

Benefits of IIoT-Enabled Predictive Maintenance Sensors

By implementing IIoT-enabled predictive maintenance sensors, manufacturers can expect the following advantages over traditional maintenance techniques:

- Reduced Unplanned Downtime: Address potential failures before they impact production.

- Lower Maintenance Costs: By preventing failures, costs associated with emergency repairs are minimized.

- Extended Equipment Lifespan: Regular monitoring leads to better care and longevity of machinery.

- Improved Safety: Predictive insights can prevent hazardous equipment failures.

Furthermore, companies utilizing predictive maintenance technologies have recorded:

- 70% Reduction in Breakdowns: Effective use of predictive data can prevent persistent breakdown issues.

- 25% Decrease in Maintenance Costs: Streamlining maintenance processes leads to cost savings and efficiency.

To learn more about the benefits of predictive maintenance, check out PTC’s article: What is IoT Predictive Maintenance?.

Role of Edge Devices in IIoT

Understanding Edge Devices

Edge devices play a crucial role within the IIoT ecosystem by processing data near the source, which significantly enhances performance and responsiveness.

Advantages of Edge Devices in Manufacturing

Implementing edge devices provides several benefits for manufacturing environments:

- Reduced Latency: By processing data locally, edge devices can provide immediate responses, improving real-time decision-making.

- Lower Bandwidth Usage: Local processing minimizes the need to send large amounts of data to the cloud, saving bandwidth.

- Enhanced Data Security: Processing locally can mitigate data transmission risks and enhance security protocols. OpenAI Deep Research: Revolutionary AI Tool Transforms Professional Research Capabilities

Through effective integration of edge devices, manufacturers can experience improved operational performance and faster response times.

Connectivity Protocols in IIoT

Overview of Connectivity Protocols

The success of IIoT systems heavily relies on connectivity protocols. Several key protocols are commonly utilized, including:

- MQTT (Message Queuing Telemetry Transport): Known for its lightweight messaging, suitable for low-bandwidth situations.

- OPC-UA (Open Platform Communications Unified Architecture): Facilitates interoperability across platforms and devices.

- Bluetooth: Ideal for short-range communication, useful in localized sensor networks.

- Wi-Fi: Offers high-speed connectivity, suited for areas with extensive data traffic.

Choosing the Right Protocol

Selecting the appropriate connectivity protocol is essential for ensuring reliable data transmission and system security. Considerations include:

- Bandwidth Requirements: Ensure your selected protocol can handle the expected data load.

- Latency: Lower latency is often preferable for real-time applications.

- Scalability: Make sure the protocol can support future growth and changes in technology.

- Interoperability: Compatibility with existing systems is crucial for smooth integration.

For more details on IIoT connectivity protocols, refer to ZeroTier’s guide: What is Industrial IoT (IIoT).

Top 5 Best IIoT Sensors for Manufacturing

Selecting the best IIoT sensors for manufacturing involves careful consideration of several factors, including accuracy, reliability, compatibility, and cost-effectiveness. Here are the top five IIoT sensors available:

1. Temperature and Humidity Sensors

- Features: High accuracy, wide measurement range, low power consumption.

- Benefits: Maintain optimal environmental conditions, prevent overheating, and manage moisture-related damages.

- Applications: Useful in climate control for manufacturing environments and monitoring sensitive processes.

2. Vibration Sensors

- Features: High sensitivity, multi-axis measurement capabilities.

- Benefits: Enable early detection of equipment issues, facilitating enhanced maintenance scheduling.

- Applications: Ideal for monitoring rotating machinery and implementing predictive maintenance strategies. OpenAI Deep Research: Revolutionary AI Tool Transforms Professional Research Capabilities

3. Pressure Sensors

- Features: High precision, robust and durable design.

- Benefits: Enhance process optimization and detect leaks and pressure-related anomalies.

- Applications: Essential for hydraulic systems and pneumatic equipment monitoring.

4. Flow Sensors

- Features: Non-intrusive measurement, high accuracy across a wide range.

- Benefits: Improve process control and optimize resource utilization.

- Applications: Common in fluid handling systems and chemical processing industries.

5. Proximity Sensors

- Features: Fast response time, non-contact detection mechanisms.

- Benefits: Enhance safety protocols and automate material handling processes.

- Applications: Used frequently on assembly lines and in robotic systems integration.

Comparison Chart

| Sensor Type | Features | Benefits | Applications |

|---|---|---|---|

| Temperature & Humidity | High accuracy, wide range | Prevent overheating | Climate control |

| Vibration | Multi-axis measurement | Early detection of issues | Rotating machinery |

| Pressure | Robust design | Leak detection | Hydraulic systems |

| Flow | Non-intrusive | Process control | Fluid handling |

| Proximity | Fast response | Automated processes | Assembly lines |

These sensors play critical roles in enhancing manufacturing processes and maximizing efficiency.

Implementing IIoT Sensors in Your Manufacturing Process

Step-by-Step Guide to Integration

To successfully integrate IIoT sensors into existing manufacturing systems, consider the following steps:

- Assess Current Infrastructure:

- Evaluate existing equipment to identify which areas can benefit from IIoT sensors.

- Determine specific needs and objectives within your manufacturing operations.

- Choose the Right Sensors:

- Select sensors that align with identified needs, considering aspects like compatibility and scalability.

- Refer to our “Top 5 Best IIoT Sensors for Manufacturing” section for sensor recommendations.

- Ensure Compatibility and Scalability:

- Verify that any new sensors can integrate seamlessly with existing systems and protocols.

- Plan for future scalability to accommodate developing data and operational needs. Multi Agent Systems: A Comprehensive Guide to Scaling AI Agents for Business

- Implement Data Management and Security:

- Establish robust data management practices to adequately handle the influx of data from IIoT sensors.

- Ensure there are security protocols to protect sensitive manufacturing data. OpenAI Deep Research: Revolutionary AI Tool Transforms Professional Research Capabilities

- Deploy and Monitor:

- Install the selected sensors and integrate them into your existing manufacturing processes.

- Continuously monitor their performance and data accuracy for effective management.

- Train Staff:

- Provide necessary training for employees on operating IIoT sensors and interpreting data.

- Maximize ROI:

- Regularly analyze data to identify improvement opportunities and adjust strategies accordingly to ensure maximum return on investment.

Tips for Successful Deployment

- Start with a pilot program to test sensor effectiveness before full deployment.

- Engage stakeholders early in the process to ensure buy-in and address any concerns.

- Continuously evaluate sensor performance and make necessary adjustments to maintain efficiency.

Conclusion

Selecting the best IIoT sensors for manufacturing is vital for organizations looking to leverage the benefits of Industry 4.0. By understanding their operational needs and incorporating appropriate IIoT solutions, manufacturers can significantly enhance production efficiency and overall operations.

It is time to evaluate your manufacturing processes and consider integrating IIoT solutions to maintain a competitive edge. For tailored IIoT solutions or a consultation to implement IIoT devices, feel free to reach out to us!

Additional Resources

For further insights into IIoT in manufacturing, consider exploring the following resources:

By understanding and leveraging these IIoT technologies, manufacturers can adapt to the evolving industrial landscape, driving efficiency and innovation in their operations.

FAQ

What are the key benefits of using IIoT sensors in manufacturing?

IIoT sensors provide real-time monitoring, enable data-driven decision-making, optimize processes, and facilitate predictive maintenance, leading to increased efficiency and reduced downtime.

How do IIoT sensors contribute to predictive maintenance?

IIoT sensors collect real-time data on equipment performance, which is analyzed to predict potential failures before they occur. This allows for proactive maintenance, reducing unexpected downtime and maintenance costs.

What factors should be considered when selecting IIoT sensors for manufacturing?

When selecting IIoT sensors, consider factors such as accuracy, reliability, compatibility with existing systems, scalability, power consumption, and cost-effectiveness to ensure they meet your specific manufacturing needs.

What role do edge devices play in an IIoT ecosystem?

Edge devices process data locally near the source, reducing latency, minimizing bandwidth usage, and enhancing data security. This improves real-time decision-making and overall system performance in an IIoT ecosystem.

Which connectivity protocols are best suited for IIoT applications?

The best connectivity protocols for IIoT applications include MQTT for lightweight messaging, OPC-UA for interoperability, Bluetooth for short-range communication, and Wi-Fi for high-speed connectivity, depending on the specific requirements of the application.