IIOT services

Estimated Reading Time: 12 minutes

Key Takeaways

- IIoT services integrate smart devices and sensors into industrial operations.

- Predictive maintenance minimizes downtime and reduces repair costs.

- Field service optimization enhances on-ground efficiency and decision-making.

- Big data analytics and machine learning drive actionable insights.

- Clear differences distinguish IIoT from consumer IoT for specialized uses.

Table of Contents

- The Foundations of IIoT Services

- Predictive Maintenance: Staying One Step Ahead

- Field Service Optimization: Enhancing Efficiency on the Ground

- Asset Tracking and Management: Keeping Tabs on Critical Resources

- Process Automation & Control: Revolutionizing Industrial Operations

- Big Data Analytics & Machine Learning: Driving Actionable Insights

- The Core Components That Make IIoT Possible

- IIoT vs. Consumer IoT: Key Differences and Unique Advantages

- Industrial Sectors Benefiting from IIoT Services

- The Future of IIoT Services: A Glimpse Ahead

- Integrating High Search Volume Keywords Naturally

- Real-World Success Stories and Industry Impact

- Addressing the Challenges: Security and Interoperability

- Ensuring Sustainability Through IIoT

- Conclusion: An Era of Transformation in Industrial Operations

The Foundations of IIoT Services

In today’s era of rapid technological evolution, the Industrial Internet of Things—commonly known as IIoT services—has become a buzzword in the industrial landscape. From manufacturing floors to energy grids, the impact of IIoT is profound and far-reaching. IIoT services leverage interconnected smart devices, sensors, instruments, and computers to collect, exchange, and analyze real-time data, driving improvements in productivity, safety, and efficiency across industrial operations.

As outlined on Wikipedia and further detailed by Vation Ventures, IIoT is redefining traditional industries by integrating advanced digital tools with conventional systems.

Imagine a factory floor where machines not only perform their tasks but also communicate their current status and health. The era of scheduled maintenance based solely on time intervals is over—IIoT introduces predictive maintenance, allowing timely repairs before breakdowns occur.

Predictive Maintenance: Staying One Step Ahead

One of the most remarkable aspects of IIoT services is predictive maintenance. Unexpected machine failures can disrupt operations and lead to significant losses. With continuous monitoring of machine health and performance, IIoT enables businesses to anticipate failures and schedule repairs at the ideal time.

This approach is powered by sensors and smart devices collecting real-time data such as temperature, vibration, and pressure. The analysis—often enhanced by machine learning and big data analytics—delivers actionable insights. For more details, explore resources on the Industrial Internet of Things from TechTarget.

Field Service Optimization: Enhancing Efficiency on the Ground

IIoT also brings field service optimization to the forefront. Traditionally, field service teams have worked with limited visibility. With IIoT, real-time data on equipment status empowers technicians to arrive prepared with the right parts and tools, ensuring quick and effective repairs.

For an enhanced field service experience, learn more at TechTarget.

Asset Tracking and Management: Keeping Tabs on Critical Resources

Managing assets efficiently is crucial in large-scale industrial operations. IIoT services offer robust asset tracking and management, allowing companies to monitor the location, condition, and movement of assets across the supply chain in real time.

This continuous oversight prevents losses and upholds quality control. Detailed insights on asset tracking can be found via TechTarget.

Process Automation & Control: Revolutionizing Industrial Operations

Traditionally, many industrial processes have depended on manual controls, which can lead to inefficiencies. IIoT services are revolutionizing operations by replacing manual inputs with smart, networked devices that dynamically adjust to real-time conditions.

For example, in a manufacturing setting, sensors detect when the temperature deviates from its optimal range, prompting an automatic adjustment. More insights on this process can be found at Vation Ventures.

Big Data Analytics & Machine Learning: Driving Actionable Insights

At the heart of IIoT services is the massive volume of data generated by smart devices and sensors. When analyzed with advanced big data analytics and machine learning techniques, this data delivers actionable insights that reshape industrial operations.

For example, learn about the role of AI in industrial automation from this resource and explore data-driven manufacturing in this post.

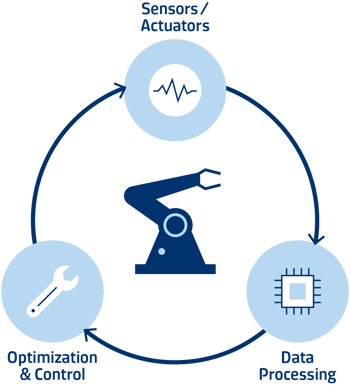

The Core Components That Make IIoT Possible

- Sensors & Actuators: These devices collect real-time data and interact with machinery. Read more on Top 5 Best IIoT Sensors for Manufacturing.

- Networking Technologies: They create secure and reliable channels for data exchange.

- Data Storage & Cloud Platforms: Robust cloud solutions centralize and manage vast amounts of industrial data.

- Analytics & Visualization Software: These tools transform raw data into actionable insights. More details at Vation Ventures.

- Security Frameworks: Critical for protecting data, as explored on Trend Micro and Vation Ventures.

IIoT vs. Consumer IoT: Key Differences and Unique Advantages

- Use Case:

- IIoT: Focused on industrial processes in factories, energy grids, and transportation networks.

- Consumer IoT: Geared towards personal devices and home automation.

- Device Grade:

- IIoT: Built to be rugged and reliable for harsh environments.

- Consumer IoT: Designed for everyday, less demanding uses.

- Security:

- IIoT: Prioritizes robust security frameworks due to critical operations.

- Consumer IoT: Generally addresses privacy and convenience with moderate security.

- Impact:

- IIoT: Enhances productivity, safety, and drives significant cost savings.

- Consumer IoT: Mainly improves convenience and lifestyle.

- Scale:

- IIoT: Operates on a large scale across multiple industrial sectors.

- Consumer IoT: Typically limited to individual homes or personal devices.

For further comparison, refer to Vation Ventures and Trend Micro.

Industrial Sectors Benefiting from IIoT Services

- Manufacturing: Real-time monitoring optimizes production lines. Learn more at TechTarget.

- Energy & Utilities: Smart grids and remote monitoring lead to resilient energy distribution.

- Transportation & Logistics: Fleet and cargo tracking optimize routes and vehicle performance, as detailed on TechTarget.

- Healthcare: Remote monitoring of medical devices ensures reliability and compliance, discussed further on Vation Ventures.

The Future of IIoT Services: A Glimpse Ahead

As industries continue to digitize, the future of IIoT services looks increasingly bright. With integration of AI, machine learning, and next-generation networking like 5G, real-time monitoring and control will become even more sophisticated, driving smarter industrial systems.

Integrating High Search Volume Keywords Naturally

High search volume keywords such as predictive maintenance, big data analytics, and machine learning are naturally woven into discussions on IIoT services. This not only boosts SEO but also emphasizes the interconnectivity of modern industrial innovations.

Real-World Success Stories and Industry Impact

Several companies have successfully integrated IIoT services into their operations. For instance, a global manufacturing firm reduced unscheduled downtime by deploying predictive maintenance across its production lines. Similarly, an energy provider utilized smart grid technology combined with real-time analytics, leading to fewer outages and improved customer satisfaction.

Addressing the Challenges: Security and Interoperability

While the benefits of IIoT are substantial, challenges such as security and interoperability persist. Ensuring robust security is paramount for maintaining data integrity and preventing unauthorized access; learn more about Industrial IoT Security Risks and Solutions. Additionally, achieving interoperability among diverse devices remains a continuous challenge, one that advancements in networking and security protocols are steadily overcoming.

Ensuring Sustainability Through IIoT

IIoT services contribute not only to operational efficiency but also to environmental sustainability. By optimizing resource usage and reducing waste via smart monitoring and proactive maintenance, industries can minimize their environmental footprint, as seen in energy utilities using smart grids.

Conclusion: An Era of Transformation in Industrial Operations

The industrial landscape is undergoing a dramatic transformation thanks to IIoT services. By leveraging predictive maintenance, field service optimization, asset tracking, process automation, and big data analytics, industries are achieving unprecedented levels of efficiency and safety.

Embracing IIoT is not merely a trend—it represents a revolution towards sustainable, efficient, and robust industrial practices. With continued advancements in AI, machine learning, and next-gen connectivity, the potential for future growth is boundless.

For further reading, please refer to the following sources:

- Overview of IIoT:

- Predictive Maintenance, Field Service, and Asset Tracking:

- Process Automation & Analytics:

Embrace the revolution of IIoT services and step into the future of industrial innovation!

FAQ

Q: What are IIoT services?

A: IIoT services integrate Internet of Things technologies into industrial settings, enabling real-time monitoring, predictive maintenance, and enhanced process automation.

Q: How does predictive maintenance work?

A: It uses sensors and real-time data analytics to monitor equipment performance, allowing for maintenance to be scheduled before failures occur.

Q: What is the difference between IIoT and consumer IoT?

A: IIoT is designed for industrial applications with higher standards for robustness, security, and scalability, whereas consumer IoT focuses on personal and home applications with convenience in mind.

Q: How do IIoT services contribute to sustainability?

A: By optimizing resource usage and reducing waste through smart monitoring and proactive maintenance, IIoT services help lower energy consumption and minimize environmental impact.

}